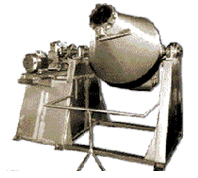

This type of machine has the most efficient design for rapid blending and mixing at low operating speeds.The design consists of shallow vertical cylinder with a cone of carefully engineered angle located at each end. Products mixed can be discharged directly into the container if desired by means of a butterfly valve fitted at the end of the cone. The blender is available either in M.S. Or S.S 304/316 materials. The drive consists of a motor coupled to a suitable gearbox to give the desired RPM.

OPTIONAL

* Flame Proof Drive. * Jacket arrangement for heating and cooling * S.S 31 6

SPECIFICATIONS

| Models | DCB 50 | DCB 100 | DCB 250 | DCB 500 | DCB 750 | DCB 1000 | DCB 1500 |

| Vol.Capacity in Ltrs. |

50 | 100 | 250 | 500 | 750 | 1000 | 1500 |

| Motor H.P. | 2 | 3 | 5 | 7.5 | 10 | 15 | 20 |

RANGE OF PRODUCTS

* Sigma Kneaders

* Attritors

* Hydraulic Dissolver

* Batch type Sand Mills

* Continuous type Sand Mills

* Bead Mills

* Ribbon Blenders

* Pug Mixers

* Planetary Mixers

* Conical Blenders

* Resin Plants

* Turnkey Projects

APPLICATIONS

* Varnishes & Paints

* Polyurethanes

* Colourants

* Inks & Dyes

* Foods

* Resins,Glues,Adhesives

* Pharmaceutical Products

* Chemicals

* Lacquers

* Cosmetics

Send Us Enquiry