Features

The optimum configuration for every product with an extremely wide choice of material for parts wetted choice of materials for parts wetted by the product including hardened and stainless steel, hard chrome-plated stainless steel, polyurethane and engineered ceramics

Wet type of grinding & dispersion mill

High efficiency - for products ranging from low to high agitator disc made of special alloy

Good wear and tear resistance - grinding chamber and agitator disc made of special alloy

Easy to use- all type of mill can be taken apart in just a few steps, allowing simple and rapid changeover to different mill configuration

Simple operation and easy setting of operating parameters

Grinding bead diameter range of 0.5-3.0 mm

Low operating and maintenance costs

Dynamic gap separator - tungsten carbide alloy steel structure for maximum wear resistance

Choice of seal design to suit your need

Application

* Paint & Ink Industry

* Pharmaceutical Industry

* Food Industry

* Agricultural and Chemical Industry

* Pigment & Dyestuff Industry

* Cosmetic Industry

Grinding Media

* Chrom Steel bead

* Zirconium silicate bead

* Zirconium oxide bead

* Glass Bead

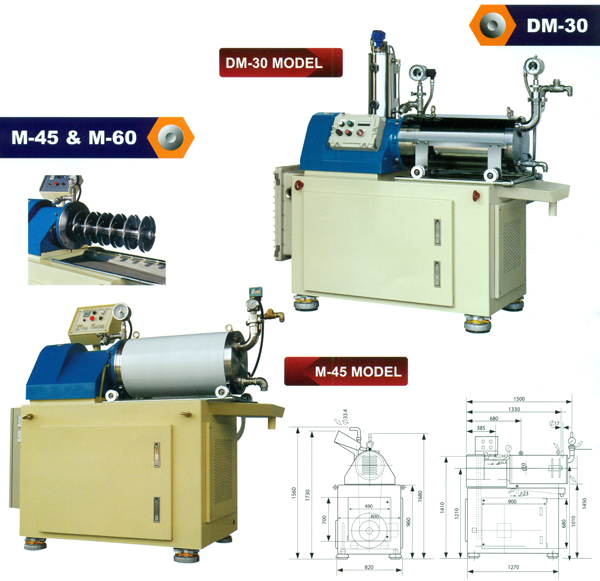

Model |

Motor Power (HP/Kw) |

Grinding Chamber (Volume, L) |

Production Volume (L/H) |

Cooling Water Consumption (L/H) |

Weight (Kg) |

Dimension L/w/H (mm) |

| S-0.3 | 2/1.5 |

0.3 |

1-20 |

100-250 |

40 |

650/420/450 |

| S-1.4 | 3/2.2 |

1.4 |

1-50 |

250-400 |

125 |

840/610/580 |

| M-5 | 10/7.5 |

5 |

20-150 |

750-1500 |

600 |

1530/850/1590 |

| M-15 | 20/15 |

15 |

50-500 |

1000-2000 |

750 |

1700/850/1630 |

| M-20 | 25/18 |

20 |

60-600 |

1000-2000 |

850 |

1820/940/1630 |

| DM-30 | 30/22 |

30 |

100-1000 |

2000-3000 |

1200 |

1850/1020/1790 |

| M-45 | 50/38 |

45 |

150-1500 |

2000-3000 |

1600 |

1850/1110/1790 |

| M-60 | 60/45 |

60 |

200-2000 |

2000-4000 |

1900 |

2205/1210/1790 |

* Data provided for reference purpose only, company reserve the right to change or modify any particular without prior notice.

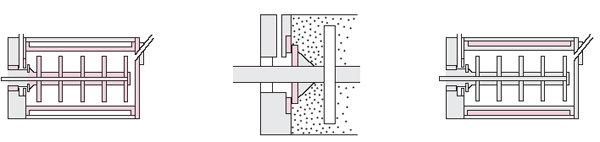

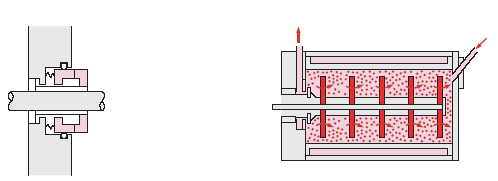

Structure

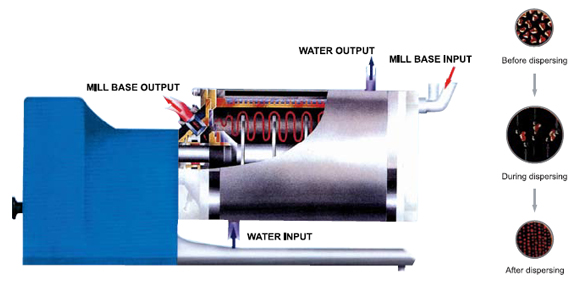

Operational Principle

Constructed of high quality material for maximum wear resistance.

The Dynamic gap separator is manufactured from extremely hard tungsten carbide alloy steel for maximum wear resistance.

High efficiency cooling system.

Choice between two kinds of shaft seal to meet customer's requirements.

Specially designed agitator disc ensures superior agitation performance

Bead Mill