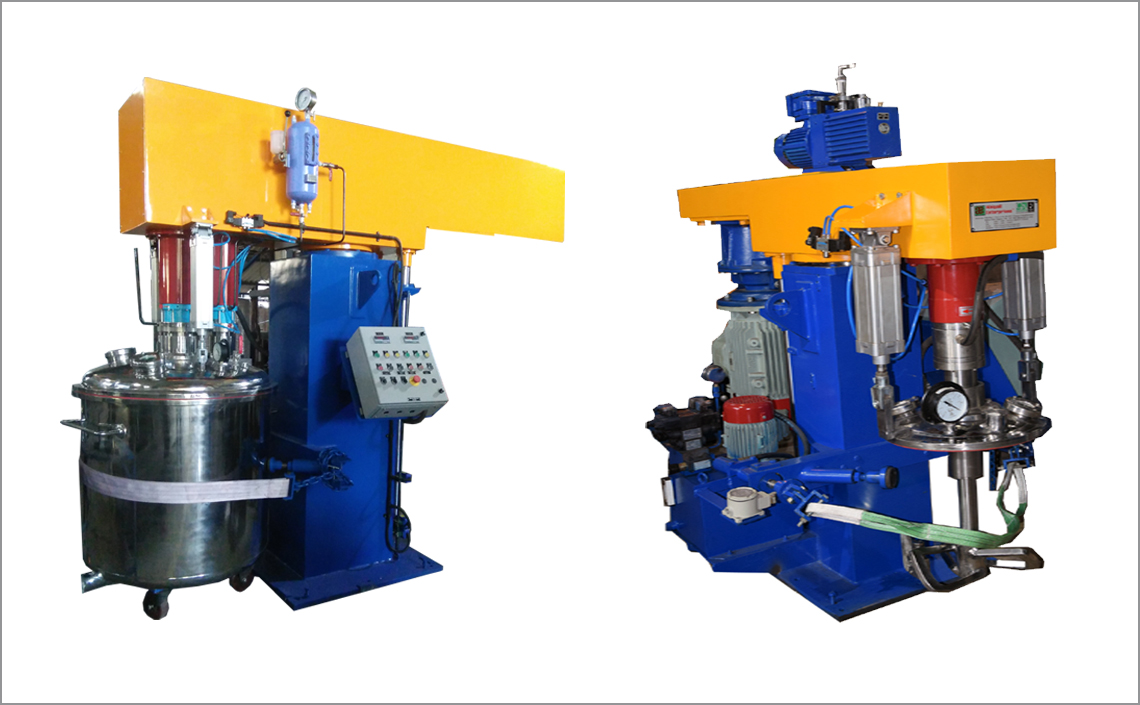

Butterfly mixers are designed to process products with medium and high viscosities. The combination of butterfly and dispersing blades provides a very high process flexibility which allows the use of this type of mixers in wide range of products. Their structural simplicity and great reliability are the reasons of their diffusion in many mixing processes. The mixer can also be supplied with a dispersing blade to process agglomerates Of solid particles.

The electronic control of the required power is a standard feature of the mechanically driven Butterfly mixers, optimizing production time and power saving. The vacuum execution option eliminates the air in the product.

The triple blade butterfly mixer is the most efficient system to handle medium and high viscosity products.The small gap between the triple blade mixing tool and the tank wall creates a shear action.

• Available in 20 ltrs to 5 Kl size, can be provided in platform mounted or stand alone design, available in multiple configurations allowing maximum flexibility to process and product.

• ATEX explosion proof (EEx-d) execution is available for hazardous working areas.

• The adjustable speed transmission driven through a VFD provides the necessary values of power and torque.

• Excellent de-aeration of the mix with vacuum.

Mixing Machinery, Industrial Stirrer, Kneading Machinery, Paint Making & Agitators, Aliperser (Stucco Mixer), Attritor, Disperser, High Speed Stirer, Double Cone Blender, Sigma Kneader, Pug Mixer, Sand Mill , Ribbon Blender, Ball Mill, Liquid Filling Machine, Triple Roll Mill, Filling Machine, Dia Mill, Dissolvers, Butterfly Mixer, Fabrication, Filling Machines, Paint Making Machinery.

© Copyright reserved Powered by MID