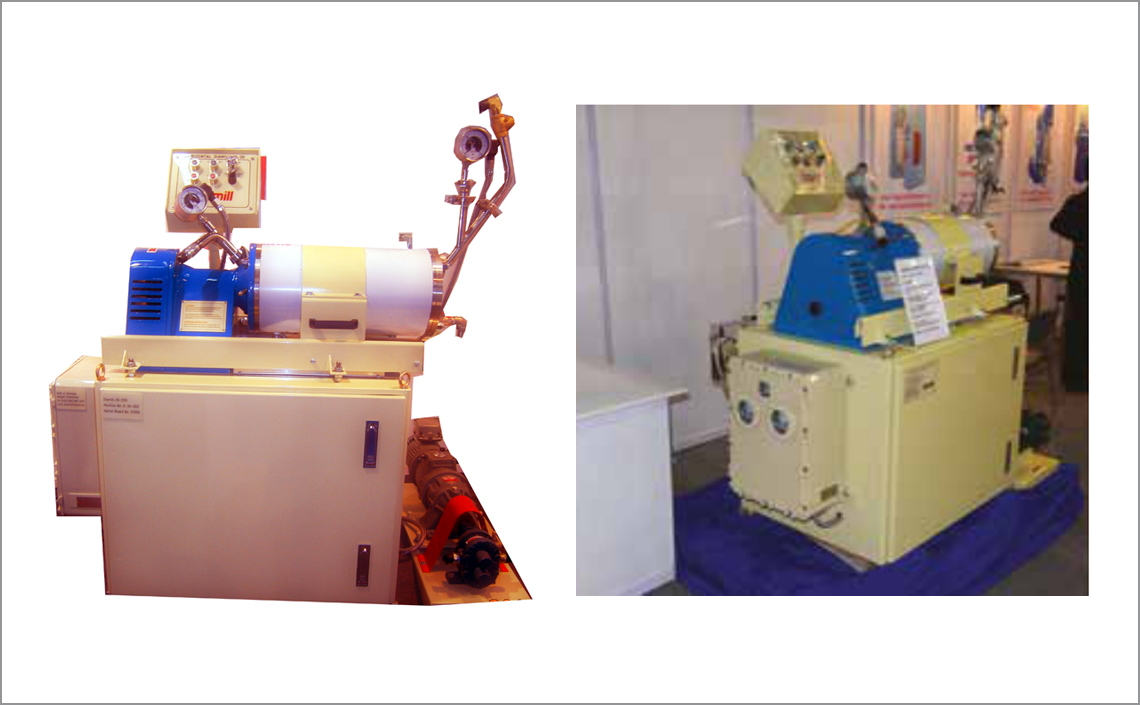

Horizontal Mills are high energy / high efficiency mills designed for dispersion and fine wet grinding. These are suitable for use in Chemical, agrochemical, pigments, paints, coatings, inks and mineral grinding processes. These mills provided much higher efficiency than sandmills, attritors, vertical bead mills. They can handle slightly higher viscosity materials. They are designed as a continuous process machine which results in higher grinding efficiency and superior process control. They are available in different shell volumes, grinding disc MOC. The grinding chamber is made of high abrasion resistance materials which gives durhbility and reduced maintenance of the machines. Very easy to operate. Grinding media used is zirconium oxide.

• Closed horizontal mill chamber requires a chiller

• Multiple mills can be used in a cascading mode to reduce process times

• Designed for use in Hazardous areas

• Easy rnaintenance as there are very few parts

• Easy to replace parts resulting in low operation costs

• Dynamic Gap separator is made of tungsten carbide alloy steel

• All parts used in the machine are extremely abrasion resistant

• Choice of seal designs are available to suit process needs

Mixing Machinery, Industrial Stirrer, Kneading Machinery, Paint Making & Agitators, Aliperser (Stucco Mixer), Attritor, Disperser, High Speed Stirer, Double Cone Blender, Sigma Kneader, Pug Mixer, Sand Mill , Ribbon Blender, Ball Mill, Liquid Filling Machine, Triple Roll Mill, Filling Machine, Dia Mill, Dissolvers, Butterfly Mixer, Fabrication, Filling Machines, Paint Making Machinery.

© Copyright reserved Powered by MID