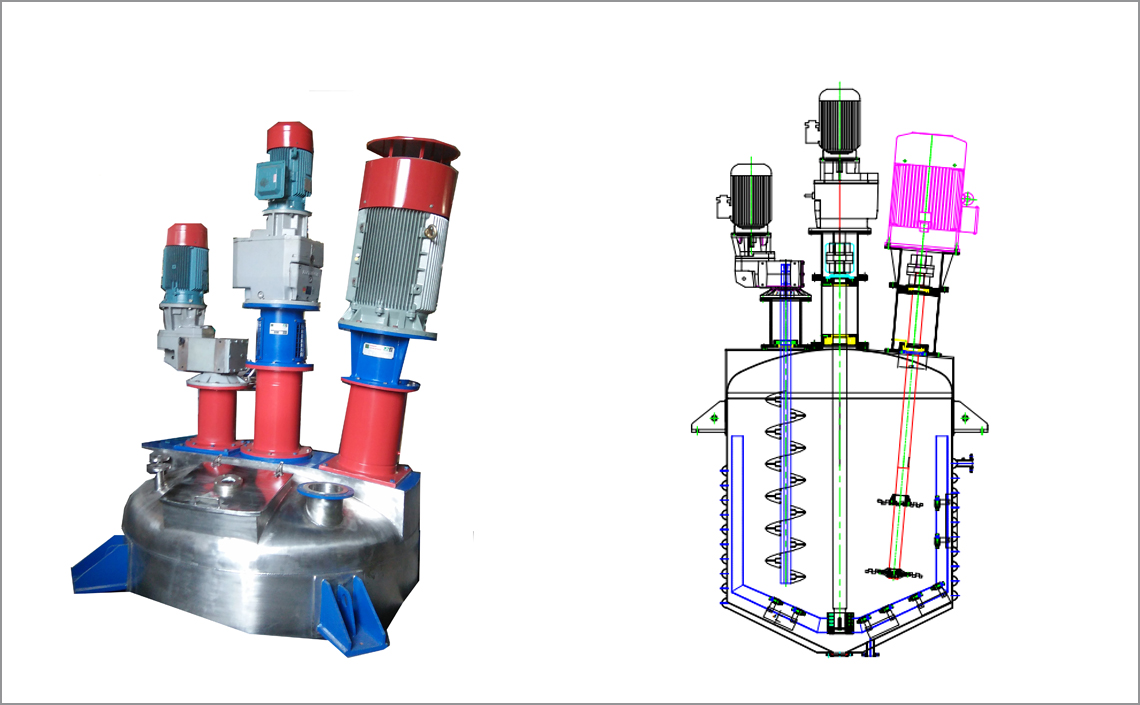

Triple-shaft mixers are universally applicable for high viscosities. Their great advantage lies in the ability to manufacture products with a very high viscosity and poor flow characteristics. Due to the high viscosity of many of the products produced in this design, the slow speed mixing impeller functions not only as a pump, moving the mass into the high speed dispersing blade, but also as a dispersing blade itself.

Triple-shaft mixers on brackets can be equipped with compression load cells. Direct dosing into the mixer is thus enabled. We also design variety of blade configurations to address a wide variety of product parameters.

• Separate driving motors and multiple impeller styles to rapidly disperse extra-high viscosity, slow-flow products.

• Mix entire batch at full speed in the raised position.

• Floor-level or lift-to-discharge through gate valve.

• Independently-driven shafts. Specially designed scraper three winged blade has an added advantage.

• Multiple blade configurations.

Mixing Machinery, Industrial Stirrer, Kneading Machinery, Paint Making & Agitators, Aliperser (Stucco Mixer), Attritor, Disperser, High Speed Stirer, Double Cone Blender, Sigma Kneader, Pug Mixer, Sand Mill , Ribbon Blender, Ball Mill, Liquid Filling Machine, Triple Roll Mill, Filling Machine, Dia Mill, Dissolvers, Butterfly Mixer, Fabrication, Filling Machines, Paint Making Machinery.

© Copyright reserved Powered by MID